Means:

The industrial internet of things, or IIoT, is the use of internet of things technologies to enhance manufacturing and industrial processes.

Driving Philosophy:

The driving philosophy behind IIoT is that smart machines are better than humans at accurately and consistently capturing and communicating real-time data. This data enables companies to pick up on inefficiencies and problems sooner, saving time and money and supporting business intelligence (BI) efforts.

What it Does?

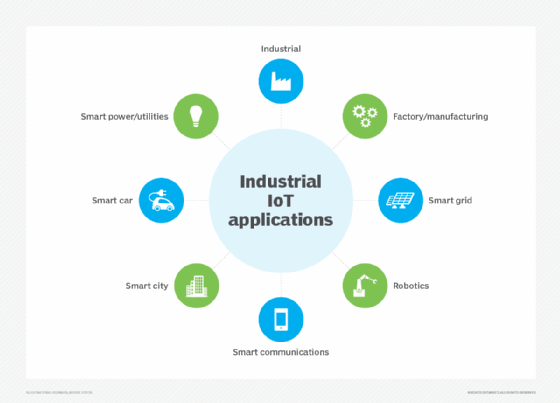

In manufacturing specifically, IIoT holds great potential for quality control, sustainable and green practices, supply chain traceability and overall supply chain efficiency.

In an industrial setting, IIoT is key to processes such as predictive maintenance (PdM), enhanced field service, energy management and asset tracking.

How IIoT works:

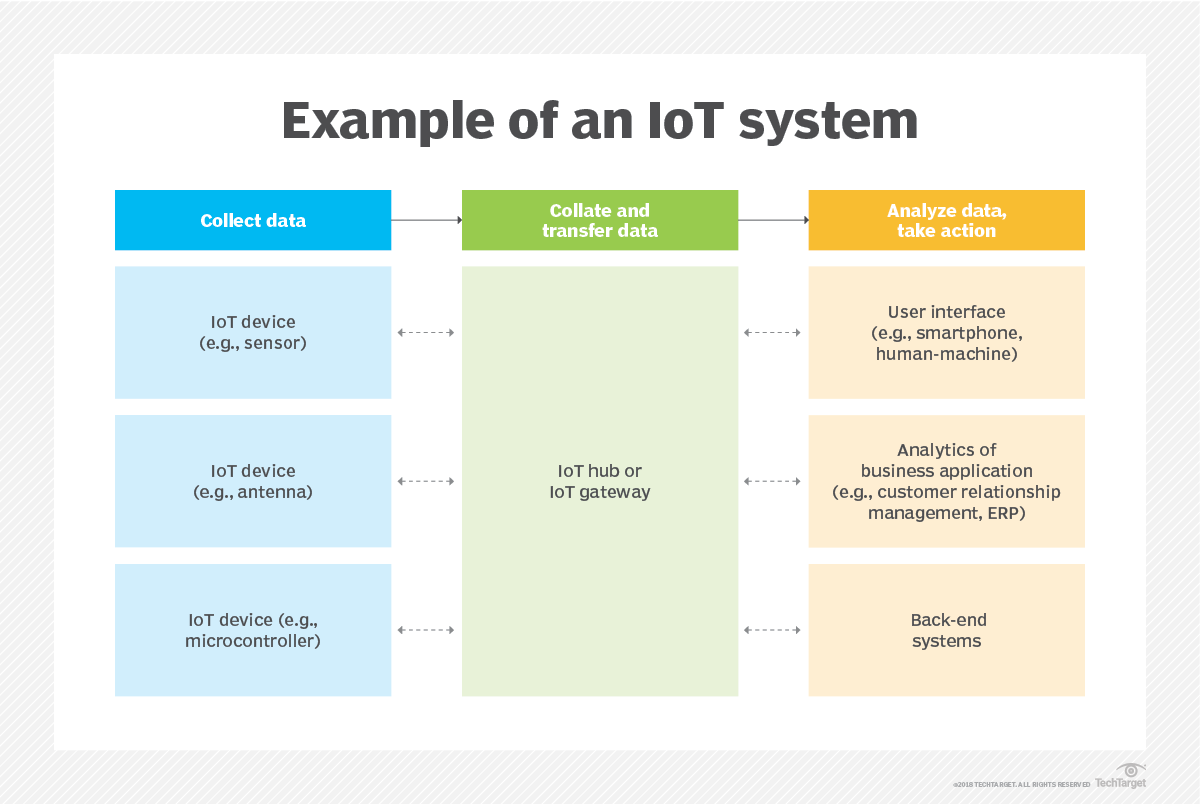

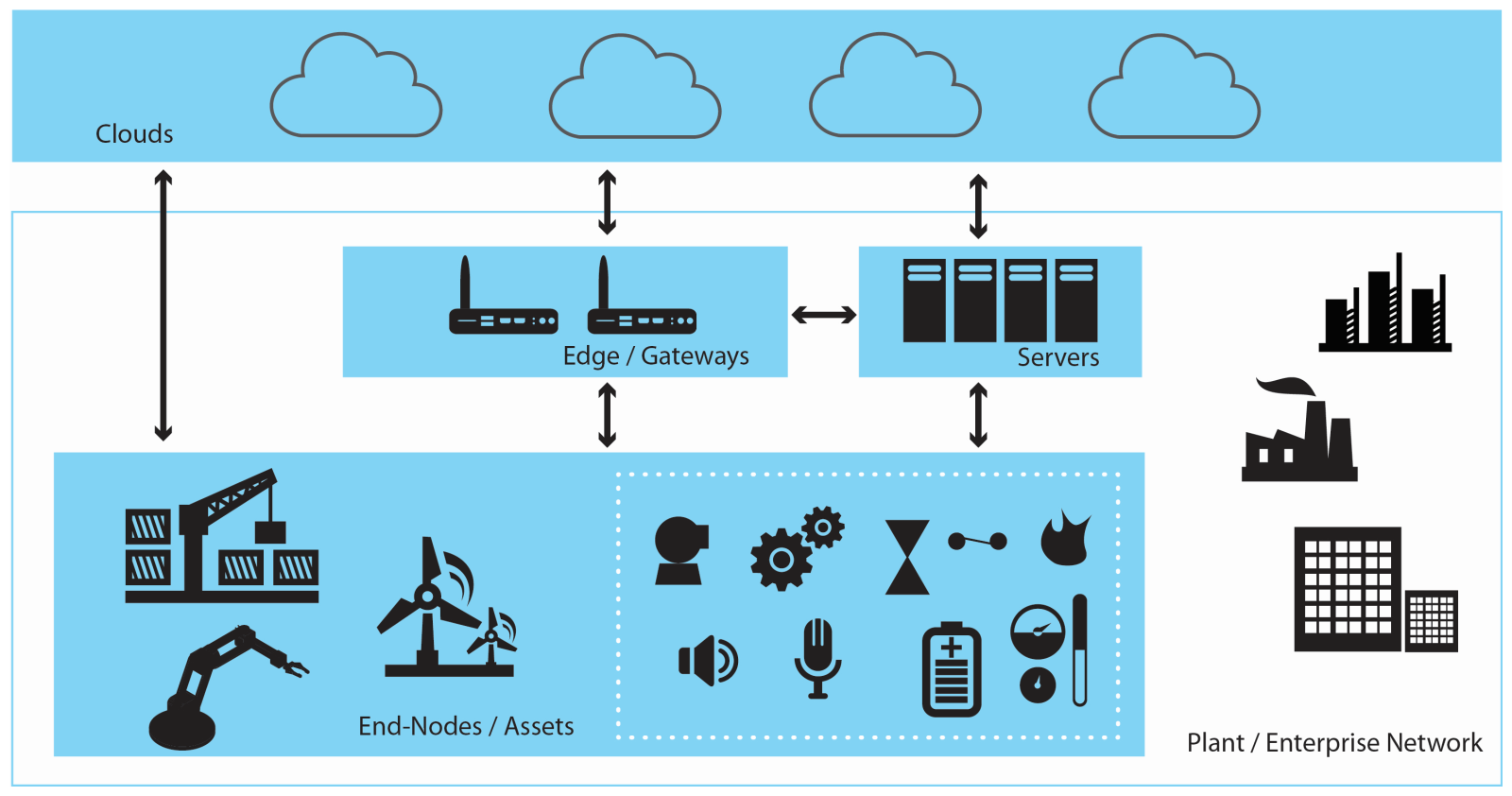

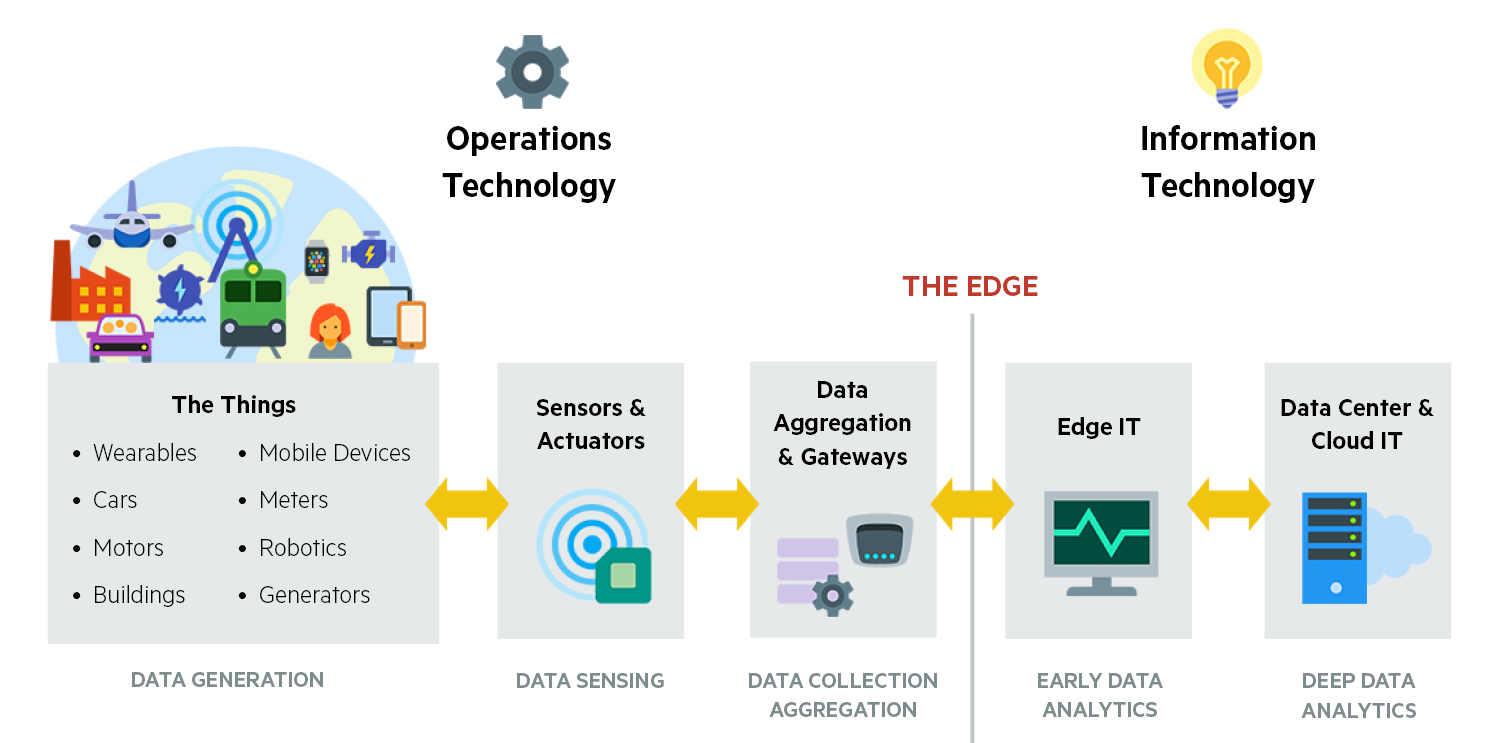

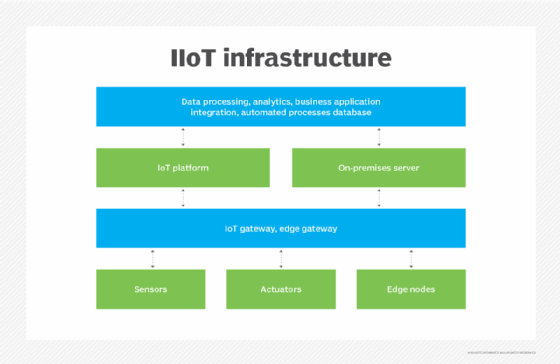

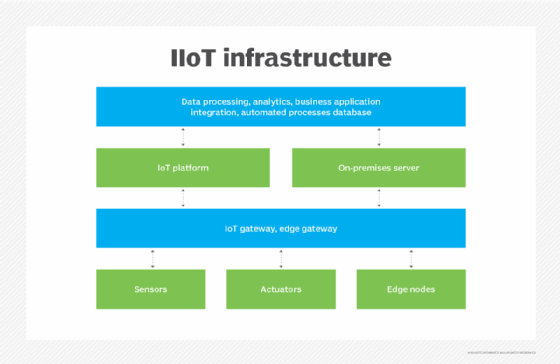

IIoT is a network of devices connected via communications technologies to form systems that monitor, collect, exchange and analyze data, delivering valuable insights that enable industrial companies to make smarter business decisions faster.

An IIoT system consists of:

- intelligent assets i.e., applications, controllers, sensors and security components -- that can sense, communicate and store information about themselves;

- data communications infrastructure, e.g., the cloud;

- analytics and applications that generate business information from raw data; and

- people.

Edge devices and intelligent assets transmit information directly to the data communications infrastructure, where it is converted into actionable information on how a certain piece of machinery is operating, for instance. This information can then be used for predictive maintenance, as well as to optimize business processes.

Industrial Business Benefits:

One of the top touted benefits the industrial internet of things affords businesses is predictive maintenance. This involves organizations using real-time data generated from IIoT systems to predict defects in machinery, for example, before they occur, enabling companies to take action to address those issues before a part fails or a machine goes down.

Improving Field Service:

Another common benefit is improved field service. IIoT technologies help field service technicians identify potential issues in customer equipment before they become major issues, enabling techs to fix the problems before they inconvenience customers.

Tracking Assets:

Asset tracking is another IIoT perk. Suppliers, manufacturers and customers can use asset management systems to track the location, status and condition of products throughout the supply chain. The system will send instant alerts to stakeholders if the goods are damaged or at risk of being damaged, giving them the chance to take immediate or preventive action to remedy the situation.

Customer Satisfaction:

IIoT permits enhanced customer satisfaction. When products are connected to the internet of things, the manufacturer can capture and analyze data about how customers use their products, enabling manufacturers and product designers to tailor future IoT devices and build more customer-centric product roadmaps.

Improves Facility Management:

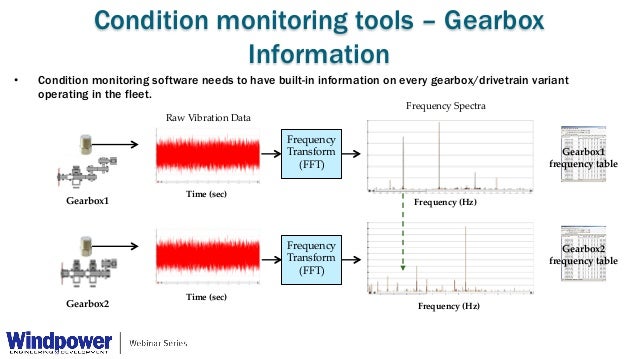

This technology also improves facility management. As manufacturing equipment is susceptible to wear and tear, as well as certain conditions within a factory, sensors can monitor vibrations, temperature and other factors that might lead to operating conditions that are less than optimal.

Applications in one PIC :

Vendors in IIoT:

- ABB

- IoT System by Cisco

- Field by Fanuc

- Predix by GE Digital

- Connected Performance Services by Honeywell

- Connyun by Kuka,

- Wonderware by Schneider Electric

- MindSphere by Siemens

INDUSTRY 4.0

Definition of I 4.0 in one PIC:

Industry 4.0 is a term often used to refer to the developmental process in the management of manufacturing and chain production. The term also refers to the fourth industrial revolution.

The term Industry 4.0 was first publicly introduced in 2011 as “Industrie 4.0” by a group of representatives from different fields (such as business, politics, and academia) under an initiative to enhance the German competitiveness in the manufacturing industry. The German federal government adopted the idea in its High-Tech Strategy for 2020. Subsequently, a Working Group was formed to further advise on the implementation of Industry 4.0.

In 2003, they developed and published their first set of recommendations. Their vision entailed that

“these Cyber-Physical Systems comprise smart machines, storage systems and production facilities capable of autonomously exchanging information, triggering actions and controlling each other independently. This facilitates fundamental improvements to the industrial processes involved in manufacturing, engineering, material usage and supply chain and life cycle management.”

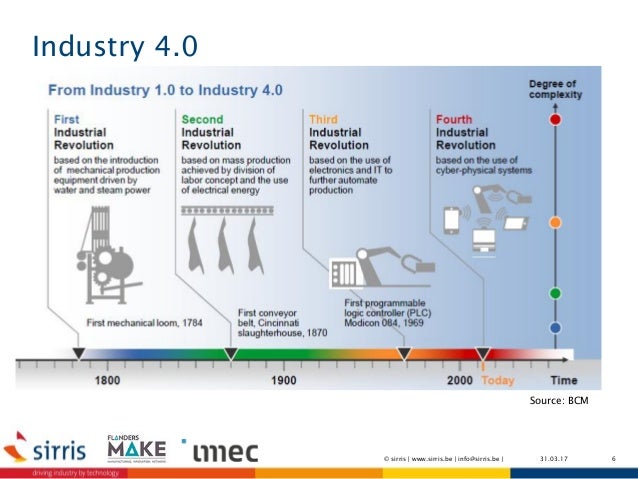

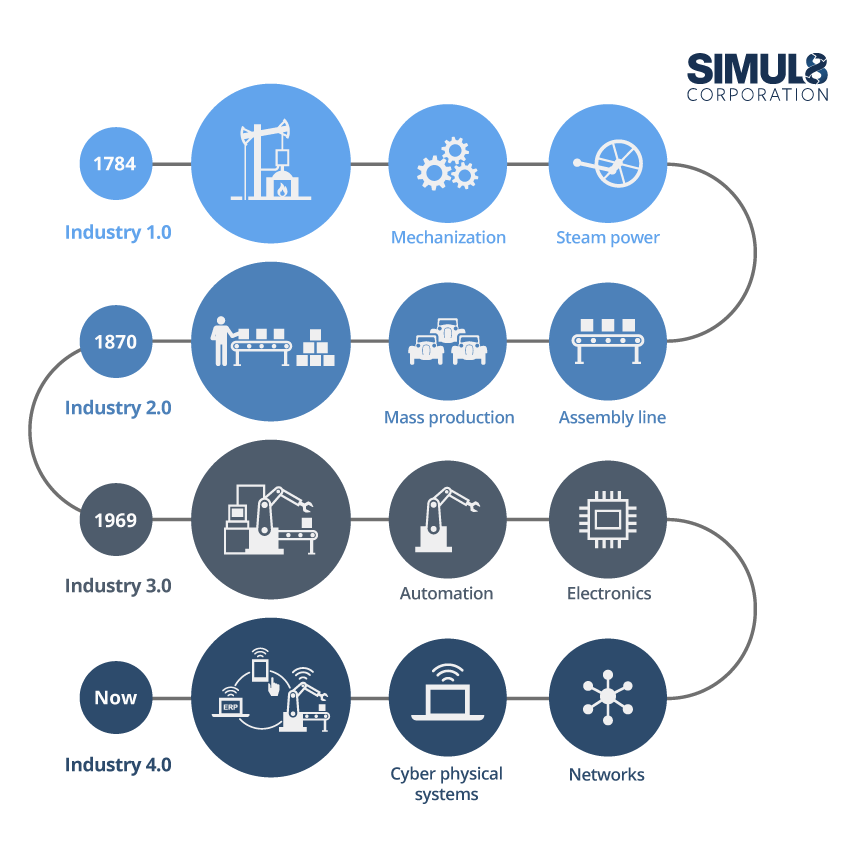

THE HISTORY BEHIND INDUSTRY 4.0

To be able to understand how Industry 4.0 became today’s buzzword, a look at its predecessors might give us a perspective on how this revolution in particular is different. The following diagram shows a timeline of the evolution of manufacturing and the industrial sector in general (Source: Deloitte).